Selecting the right printing method for your apparel business requires more than a surface-level comparison. Both Direct-to-Film (DTF) and sublimation printing have carved out significant market share in the decorated apparel industry, yet they serve fundamentally different production needs. Understanding the workflow efficiency, material compatibility, and operational requirements of each method will help you make an informed investment decision that aligns with your business objectives.

This comparative analysis breaks down the practical differences between these two popular printing technologies, providing implementation guidance specifically designed for small to medium-sized apparel brands and retail businesses entering the custom merchandise market.

Understanding the Core Technologies

Before diving into workflow comparisons, it is essential to understand how each printing method functions at a technical level.

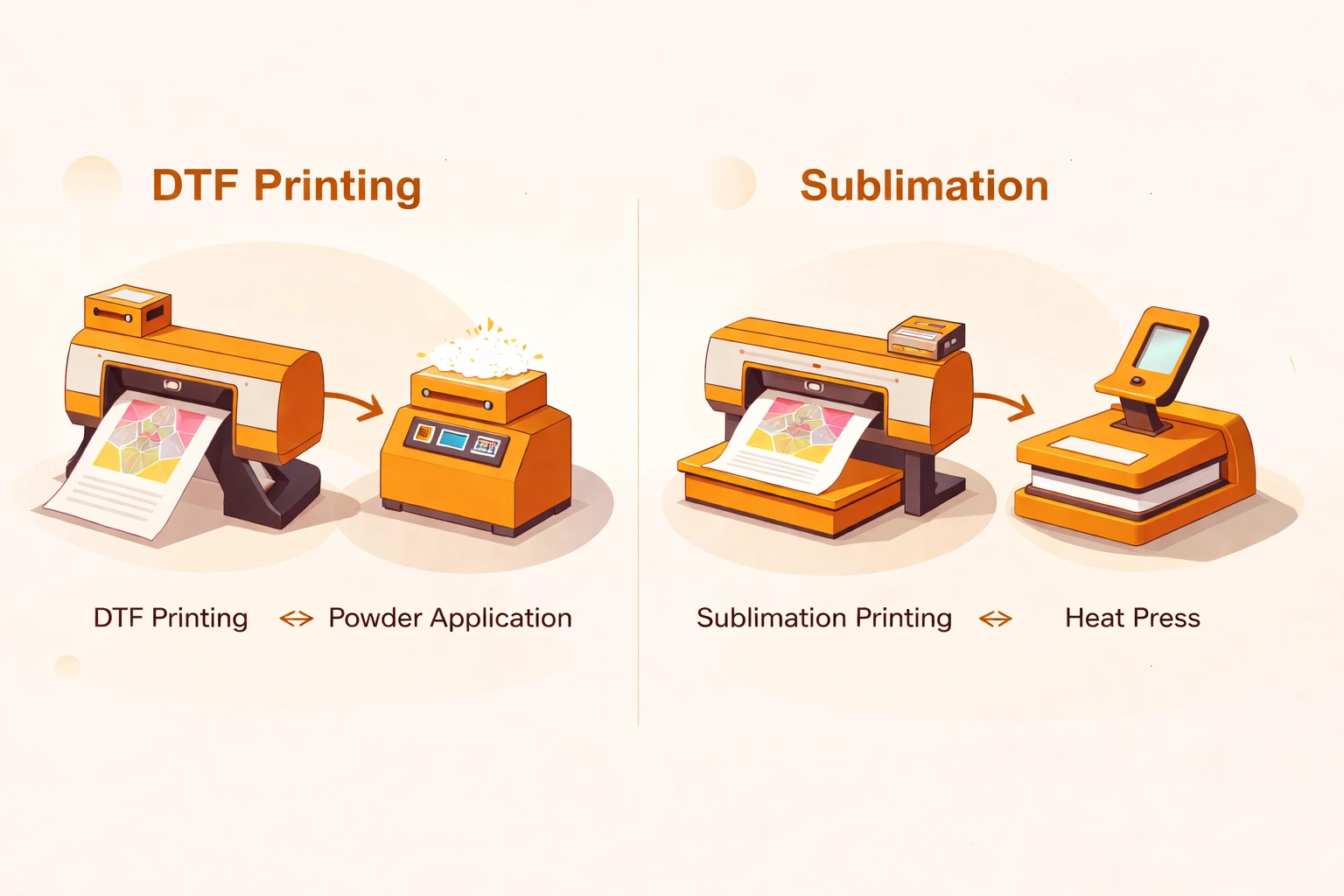

Direct-to-Film printing utilizes a specialized inkjet printer to deposit CMYK plus white ink onto polyethylene terephthalate (PET) film. A powder adhesive is then applied to the printed design, melted using a curing oven, and finally heat pressed onto the target substrate. The white ink layer serves as an underbase, allowing vibrant color reproduction on both light and dark fabrics.

Sublimation printing operates through a chemical process where heat and pressure convert solid dye particles into a gas that permanently bonds with polyester fibers at the molecular level. Designs are first printed onto specialized transfer paper using sublimation ink, then heat pressed directly onto the fabric where the dye infuses into the material structure.

Workflow Process Breakdown

The operational workflow for each method presents distinct advantages and challenges that directly impact your daily production capacity.

DTF Workflow Sequence

DTF production involves multiple sequential steps that require careful attention to timing and quality control. According to industry research, the process begins with printing the design onto PET film, followed by applying powder adhesive to the back of the print. The adhesive must then be melted in a curing oven before the transfer can be heat pressed onto the chosen substrate (PRINTING United Alliance, 2023).

Initial equipment setup requires approximately 90 minutes to install the printer, fill ink reservoirs, pull ink through the printhead nozzles, and configure RIP software. Once operational, DTF offers remarkably fast press times of approximately 10 seconds per transfer. However, the additional preparatory steps for each transfer offset this speed advantage when calculating total production time per garment.

Sublimation Workflow Sequence

Sublimation operates through a more consolidated process with fewer individual steps. Designs are printed onto transfer paper, placed onto the fabric, and subjected to heat press application. The entire workflow essentially condenses into a single print and press operation, enabling faster overall production when creating multiple transfers in sequence.

Press times for sublimation range from 1 to 5 minutes depending on substrate composition and design complexity. While individual press times exceed those of DTF, the simplified workflow often results in higher throughput for operations focused on polyester-based products. Periodic printhead cleaning represents the primary ongoing maintenance requirement.

Material Compatibility Analysis

Perhaps the most significant differentiator between these two methods lies in their substrate compatibility, which directly influences your potential product catalog.

DTF Material Range

DTF technology applies to virtually any fabric type, making it the more versatile option for businesses targeting diverse product offerings. Cotton, polyester blends, spandex, Lycra, and numerous synthetic materials all accept DTF transfers with equal effectiveness. Critically, DTF works on both light and dark garments without workflow modifications, as the white ink underbase creates an opaque foundation for vibrant color reproduction regardless of fabric color.

This broad compatibility allows apparel brands to offer a comprehensive product line using a single printing method. From heavyweight cotton tees to performance athletic wear, DTF handles the full spectrum of apparel substrates.

Sublimation Material Limitations

Sublimation requires 100% polyester or polyester-dominant fabrics containing at least 65% polyester content. The dye sublimation process depends on polymer chains within the fabric to bond with the gaseous ink, meaning natural fibers like cotton cannot accept sublimation transfers effectively.

Additionally, sublimation works primarily on light or white-colored fabrics. Because sublimation inks contain no white pigment, the underlying fabric color shows through the design. Dark substrates render sublimation prints nearly invisible. These limitations significantly narrow the product range available to sublimation-focused businesses.

Production Speed and Volume Considerations

Production capacity directly impacts profitability and customer satisfaction, making speed and volume metrics essential to your decision.

Press Time Comparison

DTF delivers faster individual press times at approximately 10 seconds per completed transfer. Sublimation requires between 1 and 5 minutes depending on the specific substrate and design parameters. For single-item production or small custom orders, DTF provides clear time savings at the heat press stage.

However, sublimation creates transfer-ready prints in one easy step without the adhesive application and curing requirements of DTF. When batch producing multiple transfers before pressing, sublimation's streamlined workflow can achieve higher overall throughput despite longer press times.

Print Area Capabilities

Sublimation supports larger print areas, with standard configurations handling up to 8.5 by 11 inches and specialized equipment capable of full garment coverage through all-over printing. DTF typically maxes out at 11 by 17 inch transfer sizes, limiting design placement options for oversized graphics or full-coverage applications.

For apparel brands focused on bold, maximalist designs or all-over print aesthetics, sublimation offers superior creative flexibility despite its material limitations.

Design Quality and Durability Assessment

Print quality and longevity influence customer satisfaction and return purchase rates, making these factors essential to brand reputation.

Visual Characteristics

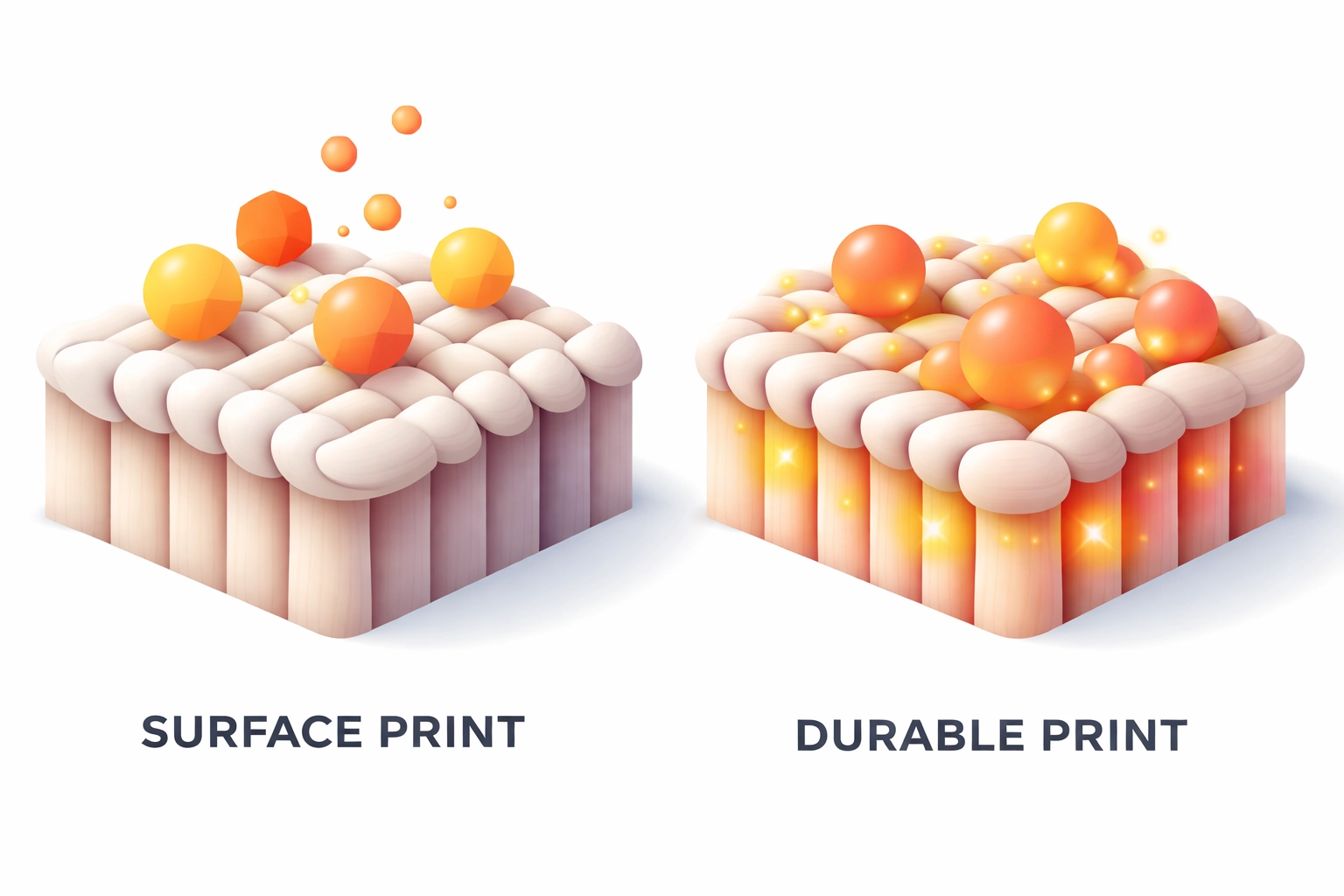

DTF prints appear as a textured layer sitting on the fabric surface with a slightly raised tactile effect. The white underbase creates excellent color vibrancy on dark garments but adds a perceptible film layer that some customers may notice during wear.

Sublimation embeds dye directly into fabric fibers, maintaining the original softness and breathability of the garment. The print becomes part of the fabric rather than a surface application, resulting in a premium hand feel. Sublimation excels particularly at reproducing realistic photographic images with smooth gradients and fine detail.

Durability Performance

Sublimation prints demonstrate superior long-term durability because the ink bonds at a molecular level within fabric fibers. Properly produced sublimation designs resist fading, cracking, and peeling throughout the garment lifespan. The print essentially becomes permanent, surviving hundreds of wash cycles without degradation.

DTF prints, while commercially durable for standard apparel applications, sit on the fabric surface rather than bonding with the fiber structure. Over time, DTF transfers may show wear patterns, particularly along seams and high-friction areas.

Cost and Investment Analysis

Budget constraints often determine which technology makes sense for businesses at different growth stages.

DTF equipment requires significantly higher capital investment, with entry-level production systems starting around $2,000 and commercial-grade configurations reaching substantially higher price points. Ongoing costs include specialized inks, PET film, powder adhesive, and maintenance supplies.

Sublimation presents lower barriers to entry with more affordable equipment costs, making it accessible for startups and hobbyists testing market demand. Consumable costs remain competitive, though substrate limitations may require maintaining separate equipment for non-polyester products.

Implementation Guidance for Apparel Brands

For small to medium-sized businesses evaluating these technologies, several strategic considerations should guide your decision.

Choose DTF if your product catalog emphasizes cotton or cotton-blend garments, includes dark-colored substrates, or requires maximum material versatility. DTF suits businesses serving diverse customer preferences without material restrictions.

Choose sublimation if your brand focuses on performance athletic wear, polyester promotional products, or all-over print designs on light-colored substrates. Sublimation excels within its material limitations and delivers superior hand feel for appropriate applications.

Many successful apparel businesses ultimately implement both technologies to maximize their product offerings. This dual-capability approach allows you to match each order with the optimal printing method based on substrate requirements and design specifications.

For additional guidance on preparing your designs for either printing method, explore our design services to ensure your artwork meets production specifications.

Conclusion

Both DTF and sublimation printing serve legitimate roles in the modern apparel decoration industry. Your selection should align with your target market, product focus, and operational priorities. By understanding the workflow differences, material compatibilities, and cost structures outlined in this analysis, you can make an informed investment decision that positions your business for sustainable growth.

Works Cited

PRINTING United Alliance. (2023). Digital printing technologies for textile applications: Industry standards and best practices. PRINTING United Alliance Publications.

Specialty Graphic Imaging Association. (2022). Sublimation printing technical guidelines. SGIA Technical Resources Division.

PRINTING United Alliance. (2023). Direct-to-film transfer printing: Equipment specifications and workflow optimization. PRINTING United Alliance Industry Reports.

Recent Comments